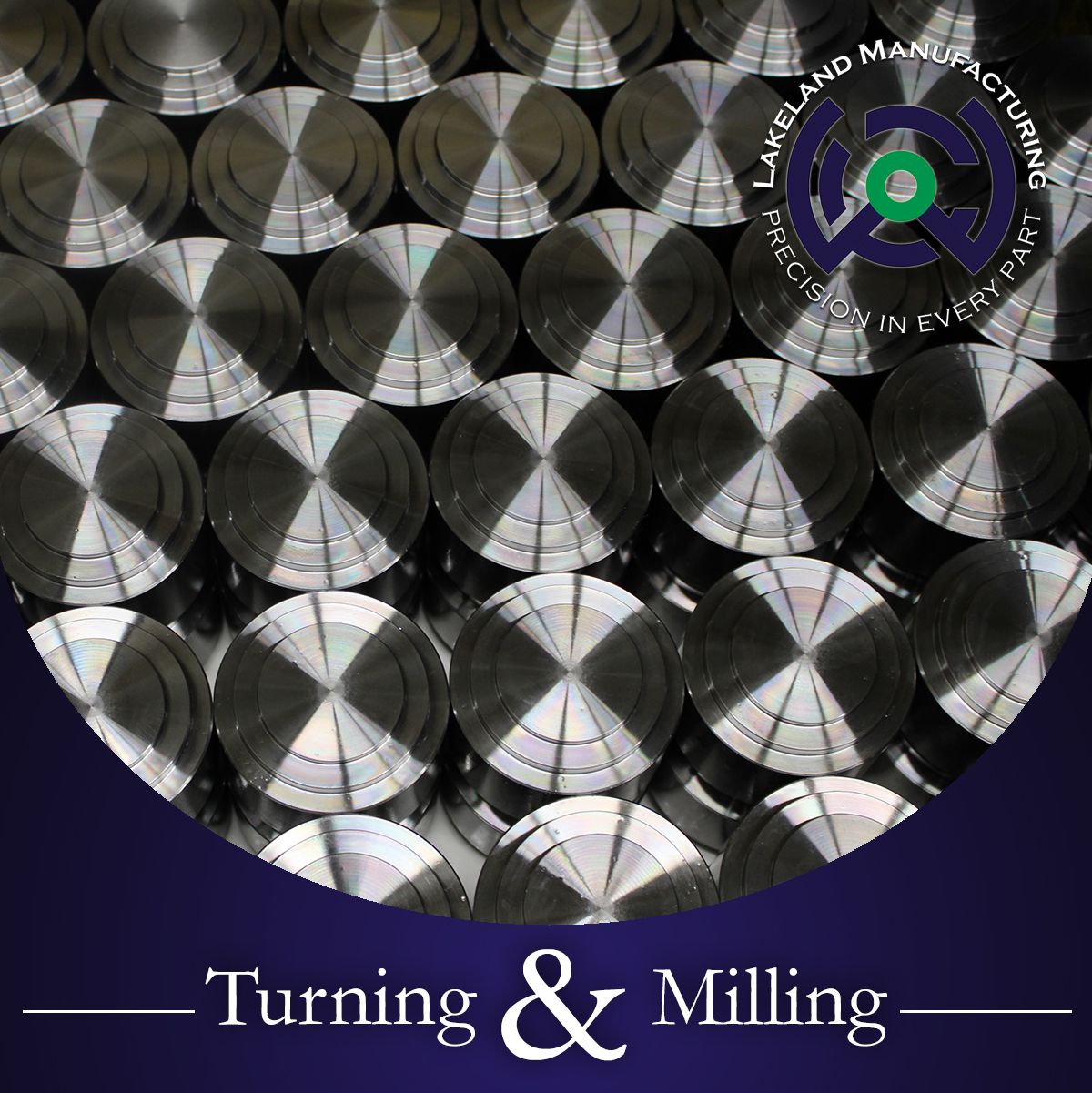

CNC milling and turning are essential processes for producing precision-engineered components with consistency and efficiency. Unlike manual machining, CNC technology enables exact replication of complex parts—time and time again—without deviation. For more than 30 years, Lakeland Manufacturing – A Marmon | Berkshire Hathaway Company has delivered exceptional quality through our commitment to precision manufacturing standards.

#Milling #Turning #MachineShop #Lathe #CNC