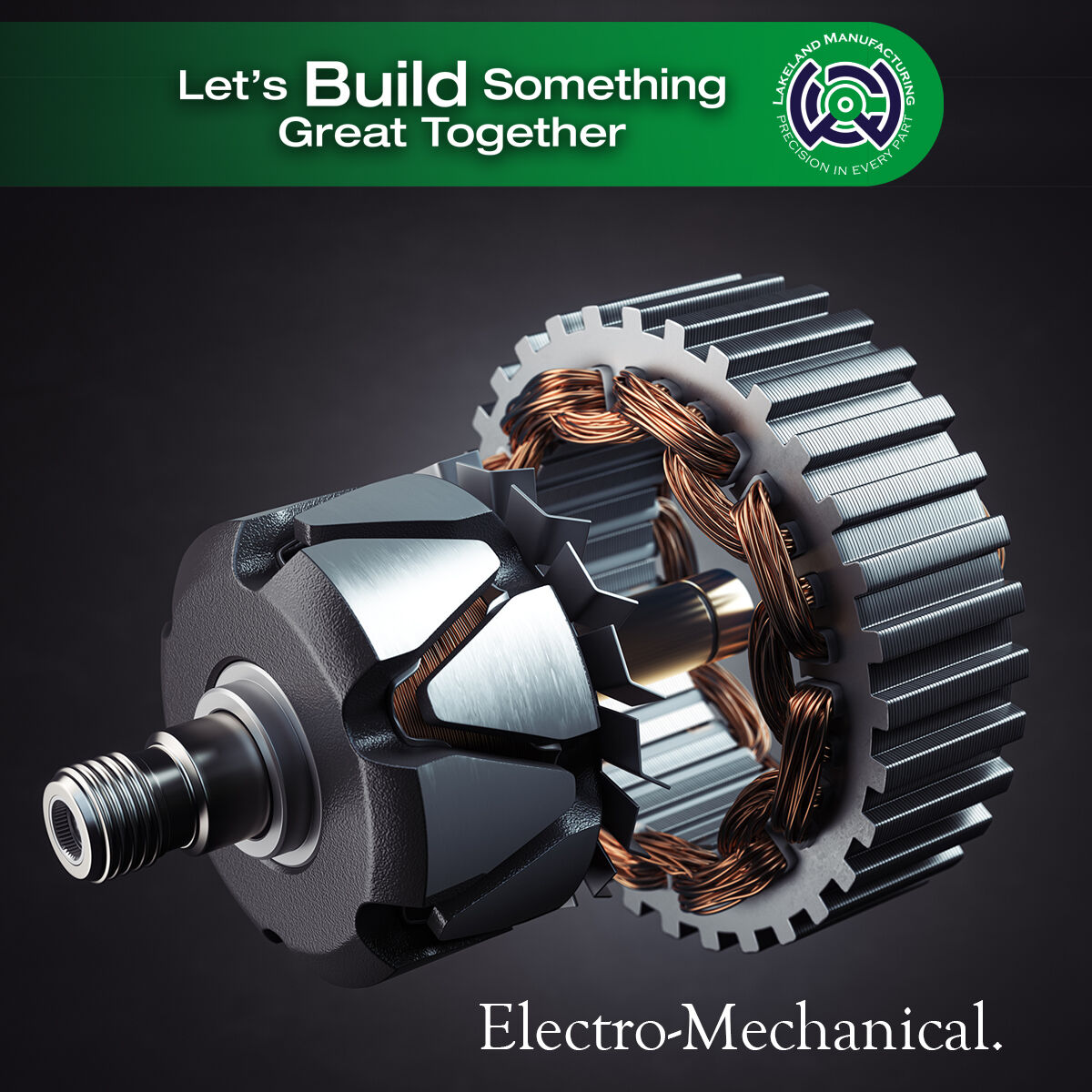

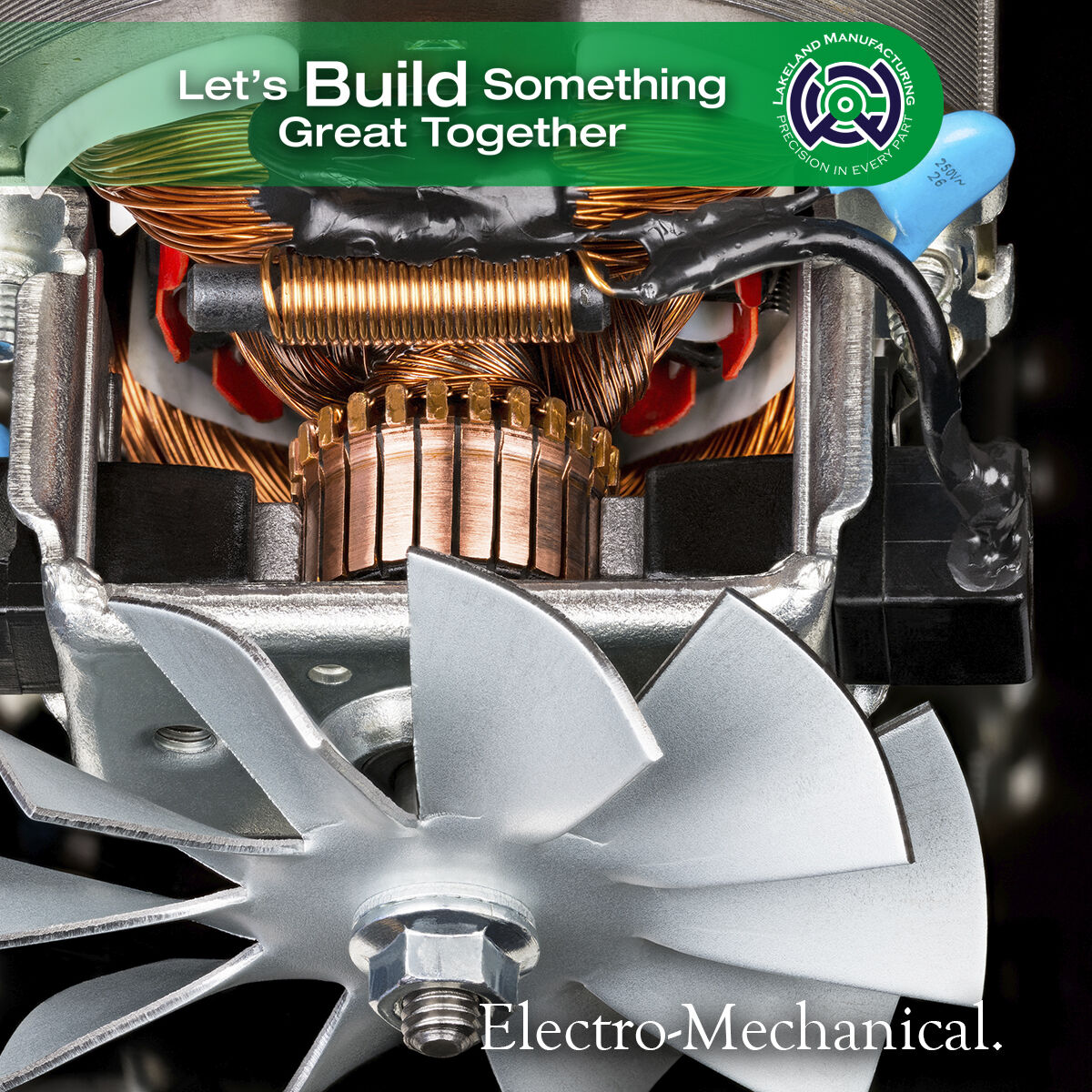

Lakeland Manufacturing – A Marmon | Berkshire Hathaway Company – delivers unmatched expertise in producing electro-mechanical products and equipment components with precision machining and tight tolerances. Our capabilities ensure every part meets stringent electrical and mechanical specifications for superior performance and reliability. Leveraging advanced technology and scalable production capacity, we provide fast turnaround times without compromising quality. Our ready-for-assembly components simplify assembly processes and reduce costs. With a strong commitment to rigorous quality control, material expertise, and collaborative partnerships, Lakeland is a trusted manufacturer of critical electro-mechanical components that meet the highest industry standards.

Contact Dan Lepak today and let’s build something great together!

#ElectroMechanical #Milling #CNCmachining #Turning